Activated carbon, renowned for its exceptional adsorption capacity and extensive surface area, plays a crucial role in water treatment, air purification, gold refining, and the food and beverage industries.

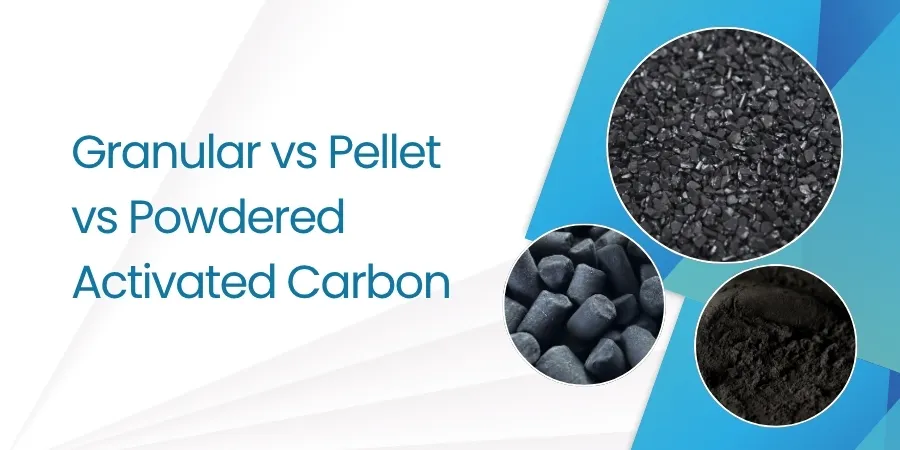

Activated carbon comes in various forms, and these differences determine its adsorption characteristics, regeneration ability, and application range.

This article offers an in-depth comparison of granular activated carbon, pelletized activated carbon, and powdered activated carbon to help you select the most suitable type for your specific needs.

What Is Granular Activated Carbon?

Granular activated carbon (GAC) is produced from raw materials such as coconut shell, coal, or wood through high-temperature carbonization and activation. The particle size generally ranges from 0.2 to 5 mm, appearing as irregular granules. It features a large surface area, well-developed pore structure, and high mechanical strength, making it ideal for both liquid and gas phase adsorption.

Production Process

The production of GAC mainly includes two stages:

- Carbonization: Heating in an oxygen-free environment at 600–800°C to remove volatile matter and form a carbon skeleton.

- Activation: Passing steam or CO₂ at 900–1100°C to develop the pore structure fully.

The final product is sieved into different mesh sizes (e.g., 4×8, 8×16, 12×40).

Main Characteristics

Granular activated carbon is one of the most commonly used adsorbents due to its strong adsorption capacity and versatile pore structure. Its key features include:

- Well-developed pore structure: Rich in micropores, mesopores, and a few macropores, resulting in a very high surface area that efficiently adsorbs various contaminants.

- Strong adsorption capacity: Suitable for both small and large molecules due to its high surface area.

- Uniform particle size and high mechanical strength: Resistant to abrasion and pulverization, minimizing equipment clogging.

- Good regeneration performance: Can be regenerated by thermal or chemical methods, extending service life and reducing costs.

Applications

The main applications of granular activated carbon include:

- Drinking water treatment: Removes chlorine, odor, color, and organic compounds, improving taste and quality.

- Industrial wastewater purification: Adsorbs organic pollutants, dyes, and heavy metals.

- Gold recovery: Used to adsorb gold ions in gold extraction processes.

- Air purification: Adsorbs VOCs and industrial gases.

- Food and beverage industry: Used for decolorization and refining of sugar, wine, and other liquids.

- Chemical and pharmaceutical industries: Solvent recovery and raw material purification.

What Is Pellet (Extruded) Activated Carbon?

Pellet activated carbon is a cylindrical form of activated carbon produced from high-quality raw materials such as coconut shell or coal through extrusion, carbonization, and activation. Due to its regular cylindrical shape, it is widely used in gas purification, water treatment, and industrial adsorption systems.

Main Characteristics

- Uniform shape: Cylindrical structure ensures good flowability and easy filling of adsorption towers.

- High mechanical strength: Resistant to breakage, providing long service life.

- Developed pore structure: High surface area and strong adsorption capacity, especially effective for organic compounds and gases.

- Chemical and thermal stability: Performs well under harsh water or gas conditions.

- Low pressure drop: Allows gases or liquids to pass through the adsorption bed efficiently.

Applications

Pellet activated carbon is mainly used for:

- Air purification: Removes harmful gases such as formaldehyde, benzene, TVOCs, odors, and smoke.

- Solvent recovery: Recovers organic solvents such as benzene, toluene, xylene, acetone, and ethanol, reducing resource loss and pollution.

- Desulfurization and denitrification: Removes SO₂ and NOx from flue gases in power plants and steel factories.

- Catalyst support: Serves as a catalyst carrier for chemical reactions like organic synthesis and exhaust gas treatment.

- Automotive emission control: Used in exhaust purification systems to remove harmful substances.

What Is Powdered Activated Carbon?

Powdered activated carbon (PAC) consists of very fine particles, typically less than 0.18 mm in diameter. It has an extremely high surface area and fast adsorption rate, making it suitable for rapid purification of liquids or gases.

Main Characteristics

- Fine particles: High surface area enables rapid adsorption.

- Strong adsorption ability: Quickly removes organic matter, odors, pigments, and some heavy metals.

- Good dispersion: Easily dispersed in water or solutions, enhancing adsorption efficiency.

- Flexible use: Ideal for short-term or high-intensity purification processes.

- Limited regenerability: Usually used once and then replaced or disposed of.

Applications

- Drinking water treatment: Removes odor, chlorine, color, and trace organic compounds.

- Industrial wastewater treatment: Removes dyes, organic pollutants, and heavy metals.

- Food and pharmaceuticals: Used for decolorization, deodorization, and purification of liquids.

- Emergency response: For sudden water contamination or short-term high-load adsorption needs.

- Air purification and industrial exhaust: Adsorbs odors, VOCs, and toxic gases.

- Soil remediation: Removes organic pollutants and heavy metals from soil.

Main Differences Among the Three Types

| Characteristics | Granular Activated Carbon | Pellet Activated Carbon | Powdered Activated Carbon |

|---|---|---|---|

| Particle Size | 0.2~5 mm | Diameter 1~5 mm | <0.18 mm |

| Shape Features | Irregular granules | Regular cylindrical | Fine powder |

| Adsorption Performance | Moderate speed, suitable for liquid adsorption | Ideal for gas adsorption, especially VOCs | Fastest adsorption rate, significant effect |

| Mechanical Strength | High | Highest | Low |

| Regeneration Ability | Multiple regenerations possible | Multiple regenerations possible | Usually not regenerated |

| Main Applications | Water treatment, air filtration, food industry | Air purification, gas treatment | Emergency treatment, food processing |

| Usage Features | Long-term stable operation | Continuous flow processing | Single-use |

Although all three types of activated carbon share the same adsorption principle, they differ significantly in particle size, surface area, adsorption rate, mechanical strength, and regeneration ability.

Particle Size and Surface Area

- Granular Activated Carbon: Irregular granules (0.2–5 mm). Offers a good balance between adsorption efficiency and flow resistance, ideal for long-term water treatment.

- Pellet Activated Carbon: Cylindrical, uniform size (1–5 mm). Large surface area and low gas flow resistance, suitable for continuous gas adsorption systems.

- Powdered Activated Carbon: Very fine (<0.18 mm). Highest surface area and fastest adsorption rate, ideal for one-time or emergency treatments.

Adsorption Performance

- GAC: Moderate adsorption rate, suitable for removing organic matter, color, odor, and some metal ions in liquid-phase systems.

- EAC: Highly developed pore structure, ideal for gaseous pollutants such as VOCs and sulfur compounds.

- PAC: Fastest adsorption rate, effectively reduces contaminants in a short time, suitable for emergency or advanced purification.

Mechanical Strength and Durability

- GAC: High strength, resistant to abrasion and hydraulic impact, suitable for repeated use.

- EAC: Highest strength, excellent compressive resistance, ideal for high-pressure and high-velocity gas systems.

- PAC: Low strength, easily lost or dispersed, generally used once.

Regeneration and Usage

- GAC: Can be regenerated thermally or chemically, offering good cost-effectiveness.

- EAC: Also suitable for multiple regeneration cycles in industrial systems.

- PAC: Not usually regenerated due to fine particle size and high loss rate.

Application Fields

- GAC: Drinking water purification, wastewater treatment, air filtration, gold recovery, and food/beverage processing.

- EAC: Air purification, solvent recovery, gas treatment, and odor control.

- PAC: Food and pharmaceutical processing, emergency water treatment, and soil remediation.

Cost and Selection Recommendations

- For long-term continuous operation and reusable applications, GAC or EAC is recommended.

- For short-term or emergency treatment, PAC is more suitable.

- For gas purification, EAC performs best.

- For water treatment and decolorization, GAC and PAC are preferred.

Conclusion

Understanding the differences between granular, pellet, and powdered activated carbon helps industries choose the most suitable solution for their purification or filtration needs.

Tingyuan Carbon offers a wide range of high-quality activated carbon products tailored to various industries and applications. Contact us to get a customized activated carbon solution for your specific requirements.