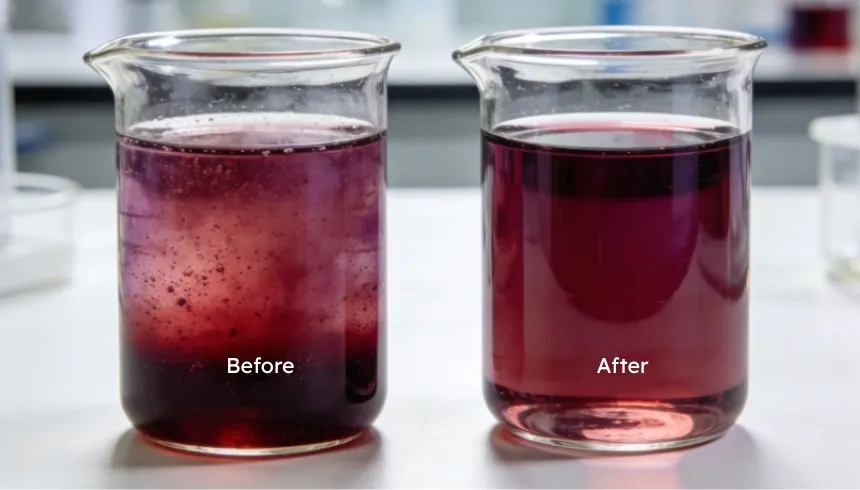

High-quality wine should present a clear and brilliant appearance, a complex and layered aroma, and a balanced, refined palate. However, in real production processes, impurities present in grape raw materials as well as by-products generated during fermentation often affect the final sensory quality of the wine.

As a highly selective adsorbent material, activated carbon can effectively remove undesirable substances while preserving the wine’s characteristic flavors and aromas.

The Necessity of Wine Purification

Even under strictly controlled winemaking conditions, wine may still face the following issues:

- Excessively dark color or uneven browning

- Off-odors generated during fermentation or storage (such as sulfur, musty, or burnt notes)

- Excessive levels of polyphenols, pigments, or trace organic impurities

- Flavor instability caused by variations in grape varieties or harvest years

These impurities not only affect the visual appeal of wine but can also introduce bitterness, musty flavors, and other quality defects. Therefore, activated carbon is commonly used for purification to enhance overall wine quality.

Mechanism of Activated Carbon in Wine Purification

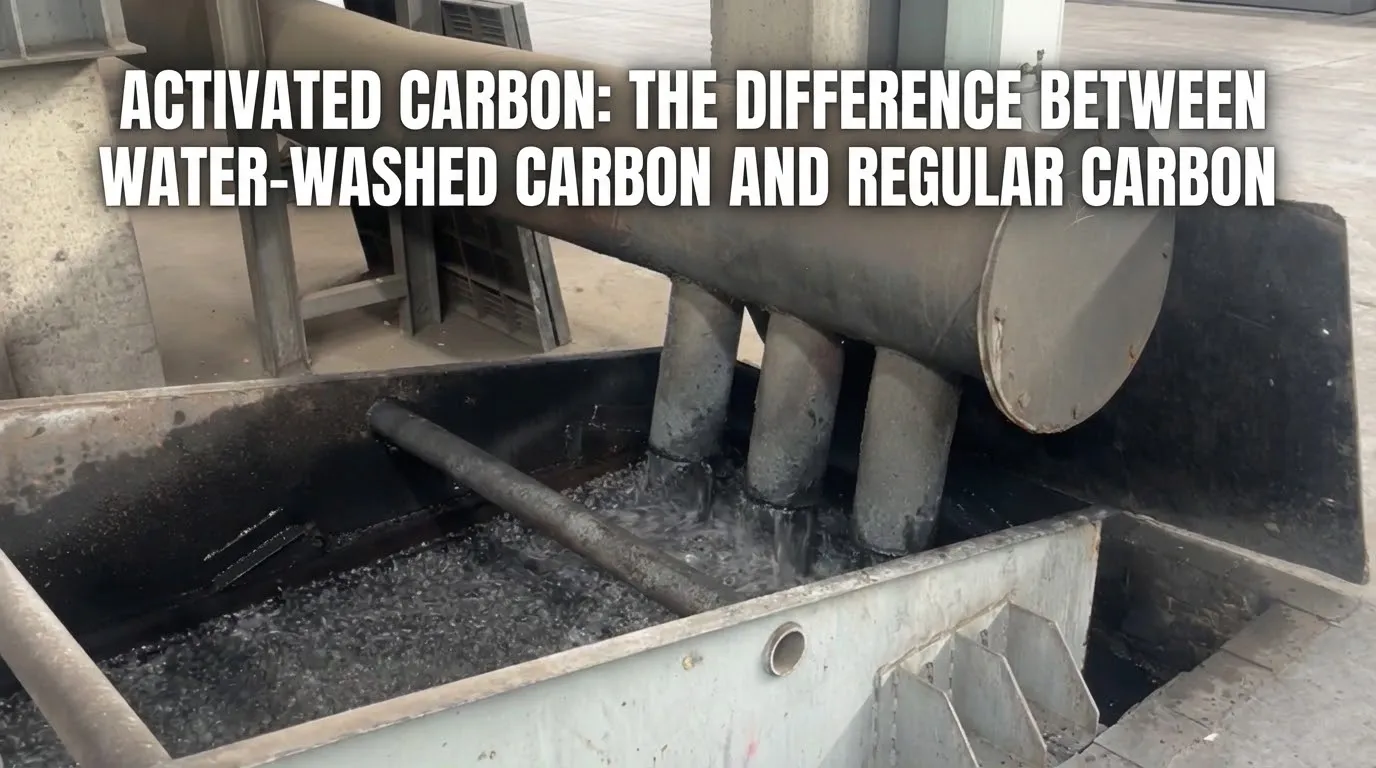

Activated carbon features a highly developed pore structure and an exceptionally large specific surface area, enabling it to remove impurities in wine primarily through adsorption.

Adsorption Mechanism

Activated carbon removes undesirable substances in wine through physical adsorption (Van der Waals forces), including:

- Phenolic compounds

- Odor-causing molecules

- Pigments

- Impurity proteins

Selective Adsorption

High-quality activated carbon is engineered with optimized pore size distribution, allowing it to:

- Efficiently remove off-flavor compounds such as TCA

- Preserve fruity aromas and wine body to the greatest extent

- Prevent excessive decolorization

Key Selection Criteria for Activated Carbon in Wine Purification

Choosing the right activated carbon is critical for successful application. The following parameters should be carefully considered:

- Food-grade certification: Must comply with food or beverage contact material standards

- Adsorption selectivity: Effectively removes target impurities without significantly reducing aroma and mouthfeel

- Ash content and impurity control: High ash levels may negatively affect wine purity

- Recommended dosage and contact time: Should be determined through bench-scale trials to avoid over-treatment

Types of Activated Carbon for Wine Purification

Selecting the appropriate type of activated carbon plays a decisive role in purification performance. Improper selection may lead to the loss of beneficial components and negatively impact wine flavor. TingyuanCarbon provides premium food-grade activated carbon specifically designed for wine purification applications.

Wood-Based Powdered Activated Carbon

Wood-based powdered activated carbon is produced from high-quality wood through high-temperature activation. It features a well-balanced pore size distribution, mild adsorption behavior, and rapid reaction kinetics, making it widely used in the wine industry.

Key Characteristics:

- Dominated by mesopores and macropores, suitable for adsorbing pigments, polyphenols, and certain odor compounds in wine

- Powdered form ensures excellent dispersion and full contact with wine, resulting in high purification efficiency

- Relatively mild adsorption helps preserve the original aroma and flavor structure of wine

- Ideal for short treatment times and fine quality adjustments

Typical Applications:

- Color correction of white wines or light-colored wines

- Removal of mild off-odors generated during fermentation or storage

- Rapid purification during post-fermentation or clarification stages

In practice, the optimal dosage of wood-based powdered activated carbon is determined through small-scale trials using low dosages to avoid excessive adsorption of flavor compounds.

Coconut Shell Granular Activated Carbon

Coconut shell granular activated carbon is produced from natural coconut shells via high-temperature activation. It offers high mechanical strength, stable pore structure, and well-developed micropores, making it more suitable for continuous or extended contact purification processes.

Key Characteristics:

- High micropore content provides excellent adsorption of small-molecule impurities and odor compounds

- Stable granular structure resists attrition, facilitating filtration and recovery

- Natural raw material with low impurity content, compliant with food-grade requirements

- Highly controllable during use, suitable for column or filtration systems

Typical Applications:

- Auxiliary purification before or after wine filtration

- Removal of slight odors introduced during storage or transportation

- Continuous, low-dosage, long-contact-time precision treatment processes

Compared with powdered activated carbon, coconut shell granular activated carbon offers a gentler and more controllable adsorption process, making it particularly suitable for applications requiring high stability of wine structure and flavor.

Contact me todayConclusion

Thanks to its outstanding adsorption performance, activated carbon plays an indispensable role in wine purification. TingyuanCarbon, as a professional activated carbon supplier, specializes in providing high-quality food-grade activated carbon for wine purification applications.

Contact us today to obtain free samples for testing and customized purification solutions.