In water treatment, food processing, pharmaceuticals, chemical manufacturing, and high-end gas purification, the purity and stability of activated carbon directly affect system performance and final product quality.

As a result, more end users and engineering companies are paying close attention to one key question when selecting activated carbon: Has this activated carbon been water-washed?

So why is activated carbon washed with water? What are the real differences between water-washed activated carbon and standard activated carbon? This article provides a systematic explanation from the perspectives of the production process, performance differences, and application scenarios.

What Is Water-Washed Activated Carbon?

Water-washed activated carbon refers to activated carbon that, after carbonization, activation, crushing, and sieving, is repeatedly washed with clean water or deionized water to remove soluble impurities, fine particles, and residual salts. It is then dewatered and dried before final packaging.

This process does not alter the pore structure of the activated carbon. Instead, it significantly improves cleanliness and operational stability.

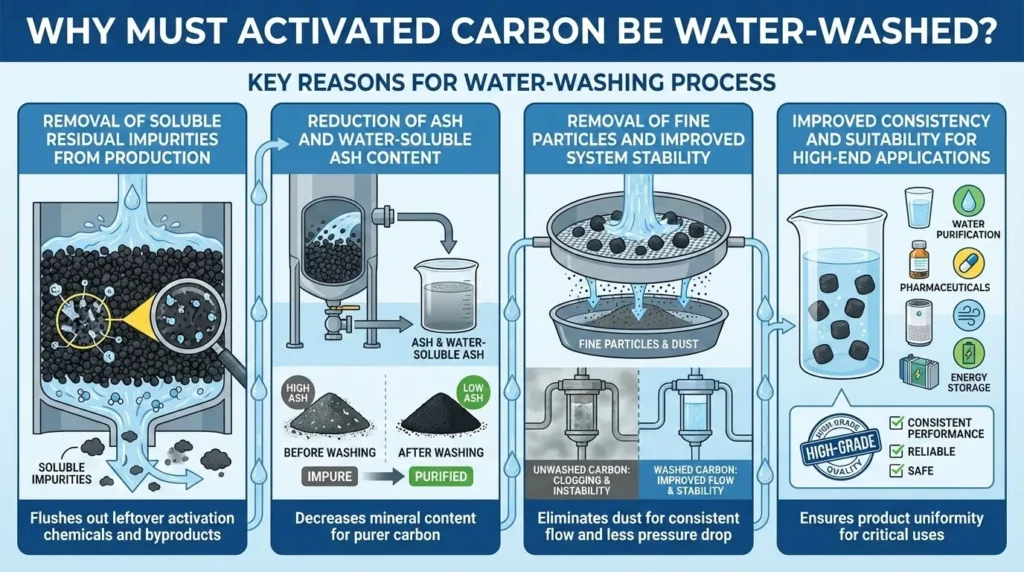

Why Must Activated Carbon Be Water-Washed?

Water washing is a critical step to ensure the purity and application safety of activated carbon, especially for high-standard water treatment and precision applications.

Removal of Soluble Residual Impurities from Production

During the activation process, activated carbon may retain:

- Soluble inorganic salts

- Residual activating agents (such as acids or alkalis)

- Carbon fines and ash particles

If not removed, these substances may be released during use, causing:

- Turbid effluent

- pH fluctuations

- Contamination of equipment or products

Water washing effectively minimizes these risks.

Reduction of Ash and Water-Soluble Ash Content

In standard activated carbon, a portion of the ash is water-soluble.

In water treatment, food, and pharmaceutical applications, such ash may:

- Increase effluent conductivity

- Affect taste, color, or product stability

Water washing significantly reduces water-soluble ash content, improving application safety and product quality.

Removal of Fine Particles and Improved System Stability

Unwashed activated carbon often contains a higher level of fine particles, which can lead to:

- Black or cloudy water during initial operation

- Filter blockage

- Increased pressure drop

- More frequent backwashing

Water-washed activated carbon greatly reduces fines through rinsing and classification, resulting in more stable system operation.

Improved Consistency and Suitability for High-End Applications

For the following applications, water washing is almost a standard requirement:

- Drinking water treatment

- Food and beverage decolorization (juice, wine, sugar solutions)

- Pharmaceutical and cosmetic raw material purification

- High-purity process water

Water washing enhances batch consistency, cleanliness, and controllability, making the product more suitable for demanding applications.

Contact me todayWater-Washed vs. Standard Activated Carbon: Key Differences

| Comparison Item | Water-Washed Activated Carbon | Standard Activated Carbon |

|---|---|---|

| Water-washed process | Yes | No |

| Soluble impurities | Low | Higher |

| Fine particle content | Low | Higher |

| Ash (especially water-soluble) | Lower | Higher |

| Initial effluent quality | Clear and stable | Often black or turbid |

| pH stability | More stable | Prone to fluctuation |

| Application scope | High-requirement uses | General industrial use |

| Cost | Slightly higher | Lower |

Does Water Washing Affect Adsorption Performance?

This is a common concern, and the answer is no.

- Water washing mainly removes impurities and fines

- Surface area, pore structure, and adsorption capacity remain essentially unchanged

- In many real-world applications, water-washed activated carbon actually performs more consistently and lasts longer

Especially in continuous operating systems, water-washed carbon often delivers a longer service life.

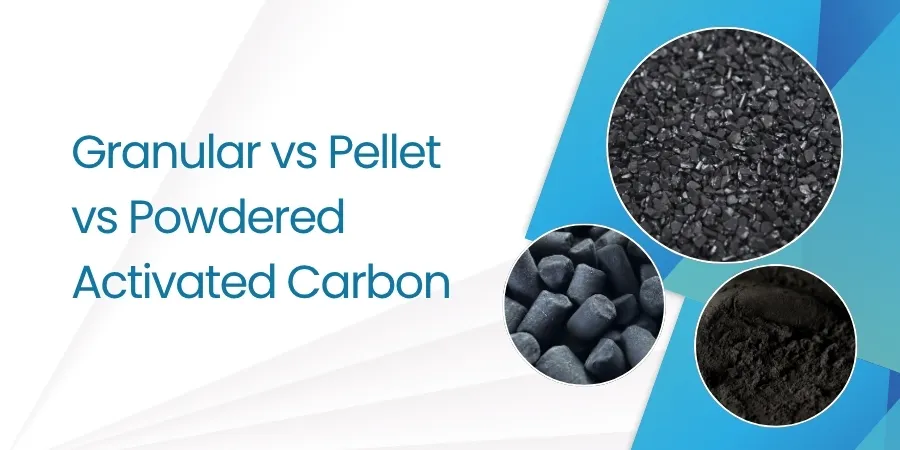

Which Types of Activated Carbon Are Suitable for Water Washing?

Water washing is suitable for various types of activated carbon, including:

- Coconut shell granular activated carbon (commonly used in drinking water and food industries)

- Coal-based granular activated carbon (industrial water and advanced wastewater treatment)

- Pelletized (extruded) activated carbon (gas purification and VOCs control)

Whether water washing is necessary should be determined based on application requirements, discharge standards, and system design.

Contact me todayHow to Select the Right Water-Washed Activated Carbon?

When sourcing water-washed activated carbon, focus on the following parameters:

- Water washing process details (single or multiple washing steps)

- Ash content & water-soluble ash

- pH range

- Fine particle content

- Adsorption indicators (iodine value, methylene blue value, CTC, etc.)

- Batch consistency and supply reliability

Professional suppliers can typically offer customized water-washing grades based on specific application needs.

Conclusion

Water washing is a key quality assurance process for high-performance activated carbon.

Compared with standard activated carbon, water-washed carbon offers clear advantages in cleanliness, stability, and application safety, making it ideal for industries with strict effluent and process requirements.

Please contact us today to get high-quality activated carbon solutions and free sample testing.