In the glucose production process, decolorization is a critical step to ensure product quality, appearance, and compliance with food-grade standards. Due to the influence of raw material sources, saccharification reactions, and high-temperature processing, crude glucose solutions often contain colored impurities such as caramel pigments, polyphenols, and protein degradation products. If these impurities are not effectively removed, they can negatively impact color value, transparency, and overall market acceptance.

Wood-based powdered activated carbon, known for its excellent adsorption performance and strong process adaptability, is widely used in glucose decolorization. This article provides a detailed overview of its application in glucose refining.

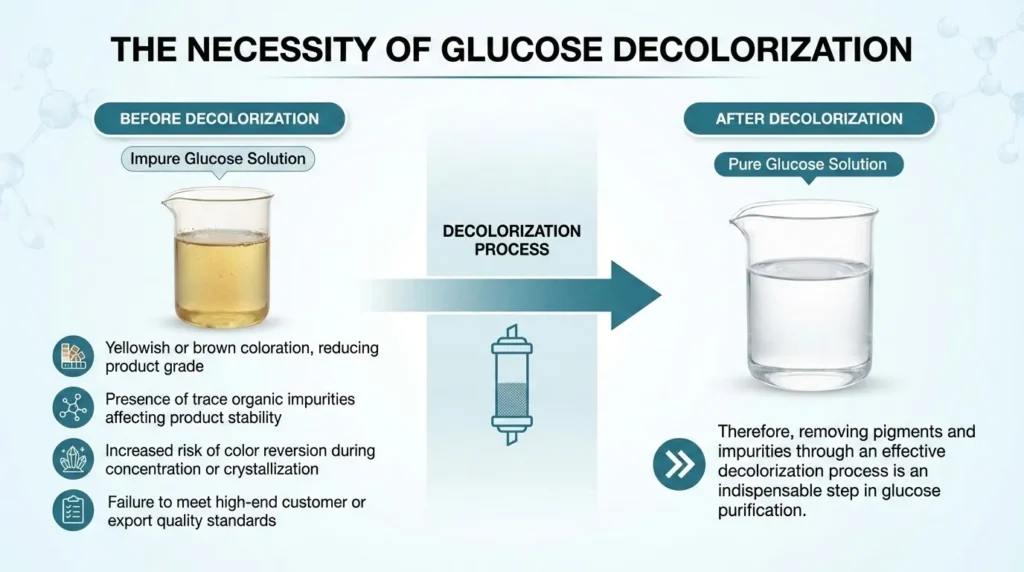

The Necessity of Glucose Decolorization

Glucose products require high standards for appearance and purity, especially in food, pharmaceutical, and fermentation applications where color control is particularly stringent. Undecolorized glucose solutions typically present the following issues:

- Yellowish or brown coloration, reducing product grade

- Presence of trace organic impurities affecting product stability

- Increased risk of color reversion during concentration or crystallization

- Failure to meet high-end customer or export quality standards

Therefore, removing pigments and impurities through an effective decolorization process is an indispensable step in glucose purification.

Contact me todayDecolorization Mechanism of Wood-Based Powdered Activated Carbon

Wood-based powdered activated carbon is produced from high-quality wood through carbonization and activation processes. It features a highly developed mesoporous and macroporous structure and a large specific surface area, providing exceptional adsorption capacity for large-molecule colorants.

Its primary decolorization mechanisms in glucose processing include:

- Physical adsorption: Removal of caramel pigments, polyphenols, and other colored organic compounds through an extensive pore structure

- Surface chemical adsorption: Interaction between surface functional groups and specific impurities

- Rapid dispersion: Powdered form enables quick and uniform dispersion in glucose solutions, enhancing contact efficiency

These characteristics allow wood-based powdered activated carbon to significantly reduce color levels in glucose solutions within a short period.

Why Choose Wood-Based Powdered Activated Carbon for Glucose Decolorization

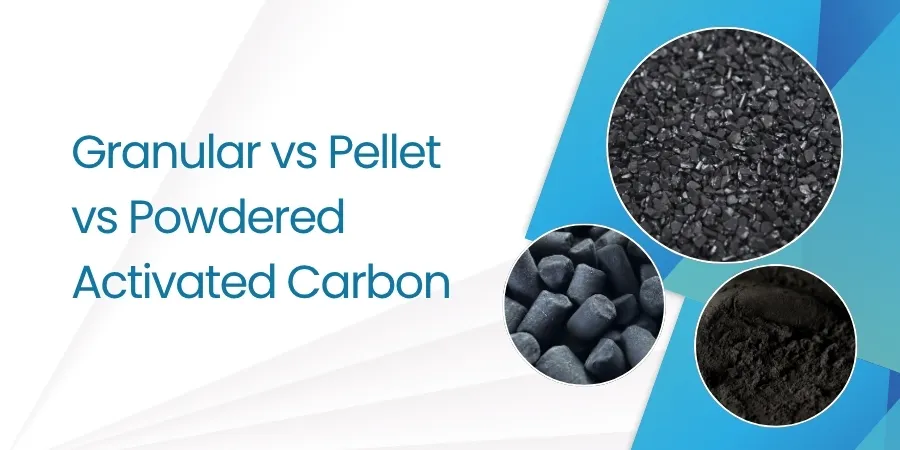

Compared with coal-based or coconut shell activated carbon, wood-based powdered activated carbon offers distinct advantages in glucose decolorization applications:

- High decolorization efficiency: Excellent adsorption of large-molecule pigments and colloidal impurities

- Fast reaction rate: Powder form provides a large contact area and short treatment time

- Low ash and impurity content: Ideal for food-grade and high-purity glucose production

- Good filtration performance: Optimized particle size distribution facilitates downstream solid–liquid separation

- Cost-effective: High decolorization efficiency per unit dosage ensures favorable overall economics

As a result, wood-based powdered activated carbon has become one of the most widely used decolorization materials in the glucose industry.

Contact me todayKey Performance Indicators for Wood-Based Powdered Activated Carbon in Glucose Decolorization

When selecting activated carbon for glucose decolorization, the following parameters are particularly important:

- Decolorization rate / decolorization power: Directly determines color removal efficiency

- Specific surface area: Influences adsorption capacity and reaction efficiency

- Molasses value: Indicates adsorption performance for large organic molecules and dark-colored impurities

- Ash content: Lower ash content minimizes impact on product purity

- Moisture content: Excess moisture affects dosage accuracy and operational stability

- Filtration rate: Directly affects production efficiency and filtration system load

For glucose solutions with different concentrations and process conditions, it is essential to select powdered activated carbon with matching performance characteristics. TingyuanCarbon can provide the most suitable wood-based powdered activated carbon products based on your specific decolorization requirements.

Application Method of Wood-Based Powdered Activated Carbon in Glucose Decolorization

In industrial operations, wood-based powdered activated carbon is typically applied as follows:

- Add the activated carbon to the glucose solution according to process requirements

- Ensure thorough contact under controlled temperature and agitation conditions

- Maintain sufficient contact time to achieve optimal decolorization

- Separate activated carbon from the glucose solution through filtration

- Proceed to subsequent concentration or crystallization steps

By properly controlling dosage, temperature, and contact time, effective decolorization can be achieved while minimizing glucose yield loss.

Contact me todayConclusion

As market demands for glucose products continue to rise in terms of appearance, purity, and stability, high-performance wood-based powdered activated carbon plays an increasingly important role in decolorization processes.

Contact us today to obtain premium wood-based powdered activated carbon samples and customized decolorization solutions tailored to your production needs.