Mercury pollution has become a key focus area in global environmental protection. Flue gases from coal-fired power plants, waste incineration, and other industries contain elemental mercury and oxidized mercury, which pose serious threats to human health and the ecosystem.

As a highly efficient adsorbent, activated carbon plays an irreplaceable role in mercury removal from flue gas. This article systematically analyzes the role of activated carbon in mercury removal, providing technical support for industrial enterprises.

Major Sources and Hazards of Mercury Pollution

During energy development and industrial production, mercury often exists as an accompanying impurity in various raw materials and process media, being released under high temperature or chemical reaction conditions. Common sources include:

- Raw Material Input: Natural trace mercury content in coal, ores, and other raw materials

- High-Temperature Transformation: Mercury released as gaseous elemental mercury (Hg⁰) during combustion

- Oxidation Reaction: Some elemental mercury oxidized to divalent mercury (Hg²⁺) in flue ducts

Elemental mercury has extremely high volatility and stability, capable of long-distance atmospheric transport. Once entering water bodies, it can be converted to methylmercury by microorganisms, bioaccumulating through the food chain and ultimately damaging the human nervous system.

Basic Principles of Mercury Removal by Activated Carbon

Mercury removal by activated carbon relies on several synergistic mechanisms:

Physical Adsorption

Activated carbon features highly developed micropores and mesopores, capable of adsorbing gaseous or liquid mercury molecules through van der Waals forces, suitable for capturing low-concentration mercury.

Chemical Adsorption

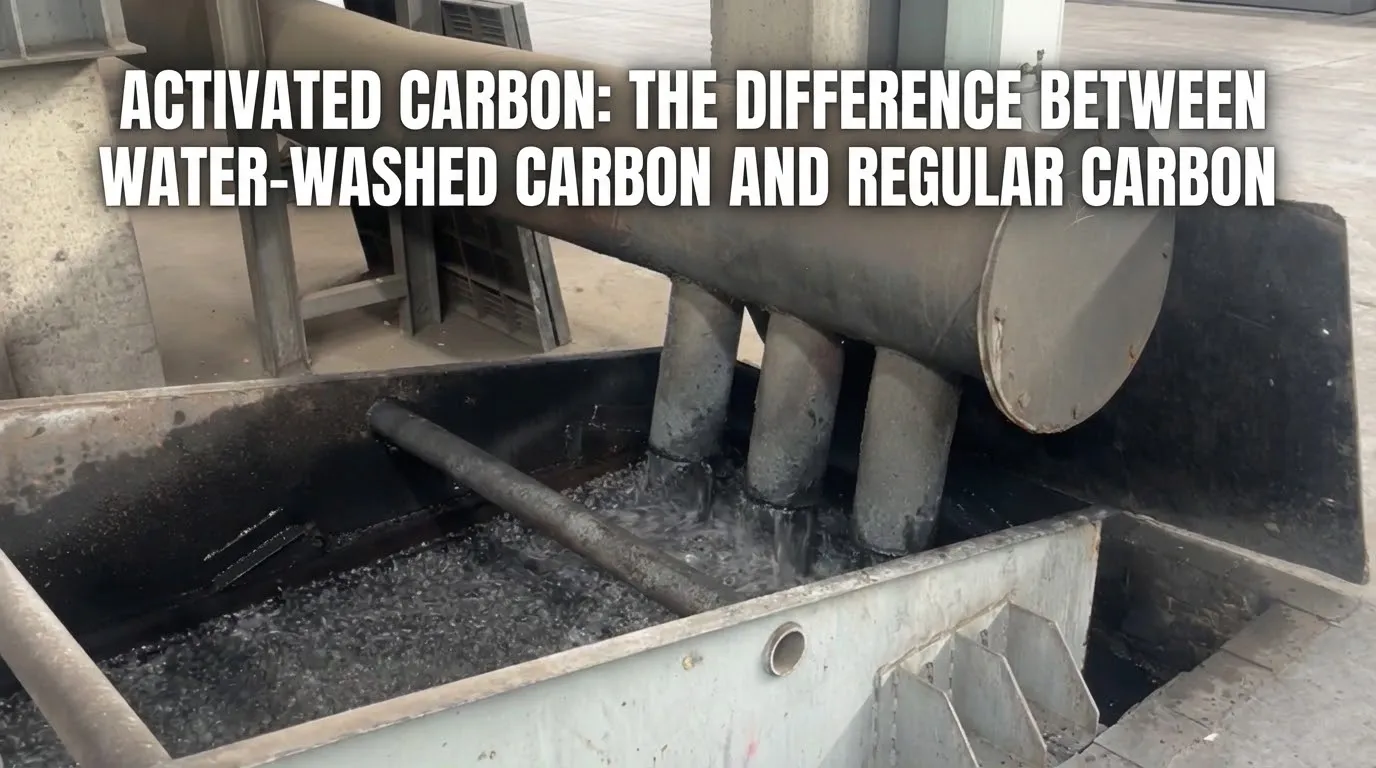

Regular activated carbon has limited adsorption capacity for elemental mercury (Hg⁰). Therefore, in practical engineering, impregnated activated carbon is often used to achieve efficient mercury removal through chemical reactions.

- Surface oxygen functional groups promote Hg⁰ oxidation to Hg²⁺

- Sulfide modification enhances chemical affinity for mercury

Applications of Activated Carbon in Mercury Removal

Activated carbon demonstrates excellent mercury removal performance in various industrial applications due to its unique physicochemical properties.

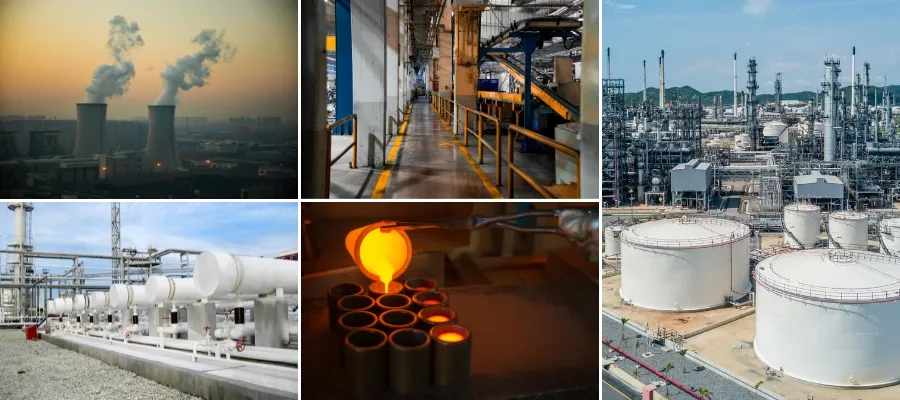

Coal Combustion and Coal-Fired Power Plant Flue Gas

Coal naturally contains trace mercury, which is released in different forms during combustion:

- Elemental Mercury (Hg⁰): Highly volatile, difficult to capture by conventional dust removal equipment

- Oxidized Mercury (Hg²⁺): Partially water-soluble

- Particulate Mercury (Hgₚ)

Coal-fired power plants are one of the largest anthropogenic mercury emission sources globally. Without effective mercury removal treatment, mercury would be directly emitted into the atmosphere, causing transboundary pollution.

Natural Gas, LNG, and Oil & Gas Fields

Natural gas carries trace mercury during formation, though at low concentrations (typically μg/m³ or ng/m³ levels), its hazards are significant:

- Mercury corrodes aluminum heat exchangers

- Creates serious safety risks in LNG facilities

- Damages downstream precision equipment

Therefore, mercury removal is an essential critical process before natural gas purification and LNG liquefaction.

Petroleum Refining and Petrochemical Industry

Crude oil and associated gas often contain mercury impurities. During refining:

- Mercury accumulates in system equipment

- Causes catalyst poisoning

- Accelerates equipment corrosion

Mercury control has become crucial for ensuring stable operation, especially in hydrogenation, cracking, and aromatics production units.

Non-ferrous Metal Smelting and Mineral Processing

Mercury is often associated with gold, silver, copper, zinc, and other metal ores:

- Mercury readily volatilizes under high-temperature smelting conditions

- Emits into atmosphere creating high-risk pollution sources

- Long-term impacts on surrounding environment and soil

This industry is also a traditional high-risk area for mercury pollution.

Chemical Production and Special Industrial Processes

Some chemical processes and products still involve mercury or mercury compounds:

- Chlor-alkali industry

- Electronic chemicals

- Special catalytic reactions

- Laboratory and pharmaceutical intermediate production

These industries typically have strict emission concentration and product purity requirements, heavily relying on mercury removal technology. Therefore, activated carbon is needed for mercury removal.

Contact me todayActivated Carbon for Mercury Removal

Different types of activated carbon vary significantly in raw material selection, pore structure, and surface modification methods, depending on industrial conditions and mercury forms. Selecting appropriate activated carbon types is key to achieving efficient, stable mercury removal.

Sulfur-Impregnated Activated Carbon

Sulfur-impregnated activated carbon is produced by introducing active sulfur components through special processes on high-quality base carbon, enabling it to have exceptional chemical mercury removal capabilities.

Key Features:

- High adsorption efficiency for elemental mercury (Hg⁰)

- Forms stable compounds, resistant to secondary release

- Suitable for low-temperature and ambient temperature gas environments

- Widely used in mercury removal from natural gas, LNG, and refinery tail gas

Common Forms:

- Granular activated carbon (4-10 mesh)

- Pellet activated carbon (3mm, 4mm)

Powdered Activated Carbon

In scenarios such as coal-fired power plants, powdered activated carbon is commonly employed for flue gas injection mercury removal.

Features:

- Large contact area: Small particle size with high specific surface area utilization

- Rapid reaction rate

- Suitable for efficient mercury removal in short contact times

- High flexibility, injection rate can be adjusted in real-time based on mercury concentration

TingyuanCarbon provides optimal performance activated carbon for mercury removal, with excellent purification effects and high cost-effectiveness.

Contact me todayConclusion

Activated carbon has become the preferred solution for industrial mercury removal due to its excellent adsorption performance.

As a professional activated carbon supplier, TingyuanCarbon has 20 years of mercury removal technology experience, offering a complete range of mercury removal activated carbon products and technical support. Contact us for free samples and customized solutions.