Odor pollution is increasingly drawing attention in industrial and commercial environments. Facilities such as wastewater treatment plants, food processing factories, chemical plants, and waste disposal centers often release unpleasant or even harmful gases. These emissions require professional management solutions.

Activated carbon, with its outstanding performance, has become the leading technology in the field of industrial odor control. This article provides a detailed overview of the role of activated carbon in odor control and helps you choose the right activated carbon product.

The Working Principle of Activated Carbon in Odor Control

The core mechanism of odor control using activated carbon is adsorption—the process in which gas molecules adhere to the surface of activated carbon.

Its high efficiency is attributed to the following factors:

- Large specific surface area: Our activated carbon has an extensive surface area, offering countless adsorption sites.

- Well-developed pore structure: The combination of micro- and mesopores efficiently captures odor molecules of different sizes.

- Chemical reactivity: Impregnated activated carbon can react with hydrogen sulfide, sulfur dioxide, or mercaptans, converting them into odorless substances.

Therefore, activated carbon is widely applied in air purification systems, industrial exhaust treatment, tank venting odor control, and general indoor air purification.

Applications of Activated Carbon in Odor Control

With its highly developed pore structure and excellent adsorption performance, activated carbon effectively captures and removes various odorous gases and organic pollutants. It is used in many fields for gas purification and deodorization.

Industrial Exhaust Treatment

Activated carbon is widely used in industries such as chemical manufacturing, rubber, textile, dyeing, and pharmaceuticals to remove unpleasant and harmful gases generated during production. It effectively adsorbs pollutants like benzene compounds, hydrogen sulfide (H₂S), ammonia (NH₃), and volatile organic compounds (VOCs), improving the air quality in and around factories.

Wastewater Odor Removal

Wastewater treatment plants, pumping stations, and sludge dewatering areas often emit strong odor gases such as hydrogen sulfide (H₂S), ammonia (NH₃), and methyl mercaptan. Activated carbon odor control systems can quickly adsorb and decompose these odor molecules, controlling the spread of unpleasant smells at the source and maintaining a clean surrounding environment.

Food and Beverage Production

During processes such as fermentation, beverage bottling, and flavoring production, gases like alcohols, aldehydes, ketones, and organic acids may be released. These not only affect the working environment but can also alter product flavor. Activated carbon filtration systems effectively adsorb these gaseous compounds, keeping the air fresh and ensuring both workplace hygiene and product consistency.

Waste Treatment and Composting Facilities

Landfills, composting plants, and food waste treatment centers release large quantities of odorous gases such as hydrogen sulfide, ammonia, methyl mercaptan, and organic amines during decomposition. Activated carbon filtration units can significantly reduce odor dispersion, protecting the quality of life of nearby residents and the working environment of personnel.

Air Purification and Ventilation Systems

Activated carbon is commonly used in indoor air purifiers, ventilation systems, and air filtration units to remove harmful gases and odors such as formaldehyde, benzene, and total volatile organic compounds (TVOCs).

Contact me todayTypes of Activated Carbon for Odor Control

Selecting the correct type of activated carbon is essential for achieving effective odor removal. Below are the most common types and their typical applications:

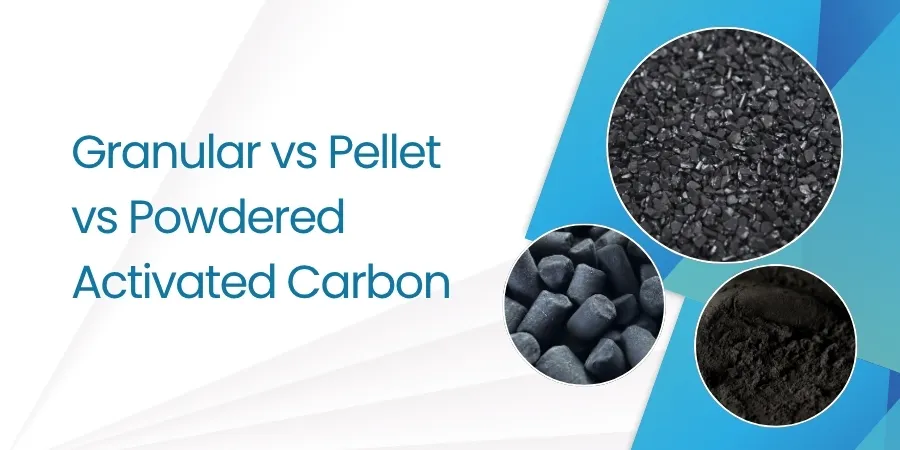

Granular Activated Carbon

Made from high-quality raw materials, granular activated carbon has irregular particle shapes, typically ranging from 0.5 to 5 mm in size. Its well-developed micro- and mesoporous structure ensures efficient adsorption of odor molecules and organic vapors from the air.

Key Features:

- Large surface area and fast adsorption rate;

- High mechanical strength, low dust generation;

- Suitable for packed filter beds and gas purification towers.

Typical Applications:

Used in air purification units, ventilation system filters, industrial exhaust odor removal, and wastewater treatment plant odor control systems—especially suitable for continuous operation systems.

Pelletized Activated Carbon

Produced through extrusion molding, pelletized activated carbon typically has a diameter of 3–4 mm. Its uniform cylindrical shape and low-pressure drop make it ideal for handling high gas flow rates.

With a consistent internal structure and excellent air permeability, it maintains high adsorption efficiency while minimizing clogging.

Key Features:

- Low air resistance, suitable for continuous systems;

- High mechanical strength and abrasion resistance;

- Easy to install, remove, and regenerate;

- Stable performance even in high-humidity or high-concentration gas environments.

Typical Applications:

Commonly used in chemical exhaust treatment, pharmaceutical plant ventilation systems, odor removal in rubber and plastic production workshops, and waste management stations.

Impregnated Activated Carbon

Impregnated activated carbon is produced by treating standard activated carbon with chemical agents (such as alkali metal oxides, sulfides, or iodides). This modification enables it to remove gases that are difficult to capture through physical adsorption alone. Combining physical and chemical adsorption mechanisms, it is especially effective for eliminating toxic, corrosive, or strongly odorous gases.

Key Features:

- Efficient removal of hydrogen sulfide (H₂S), ammonia (NH₃), sulfur dioxide (SO₂), and nitrogen oxides (NOₓ);

- Reaction products remain securely bound within the carbon structure;

- Long service life and strong treatment capacity;

- Customizable impregnation formulations for specific target gases.

Typical Applications:

Widely used in wastewater treatment plants, composting and waste transfer stations, laboratory exhaust systems, and exhaust purification for semiconductor and electronics industries requiring high-efficiency gas removal.

Contact me todayConclusion

Thanks to its large surface area, strong adsorption capacity, and regenerability, activated carbon has become one of the most reliable and commonly used materials for odor control in both industrial and air purification applications.

Whether for large-scale industrial exhaust treatment or everyday odor removal, our activated carbon provides high-performance solutions tailored to your needs.

Contact us today for customized odor control solutions and competitive pricing.