n the pharmaceutical industry, product safety, purity, and stability are always the top priorities. From raw material extraction to finished dosage forms, every stage of production must strictly control impurities, color bodies, odors, and potential harmful substances.

Thanks to its well-developed pore structure and excellent adsorption performance, activated carbon has become an indispensable purification material in pharmaceutical processes.

This article provides a detailed overview of the role of activated carbon in the pharmaceutical industry and helps you select the most suitable activated carbon products.

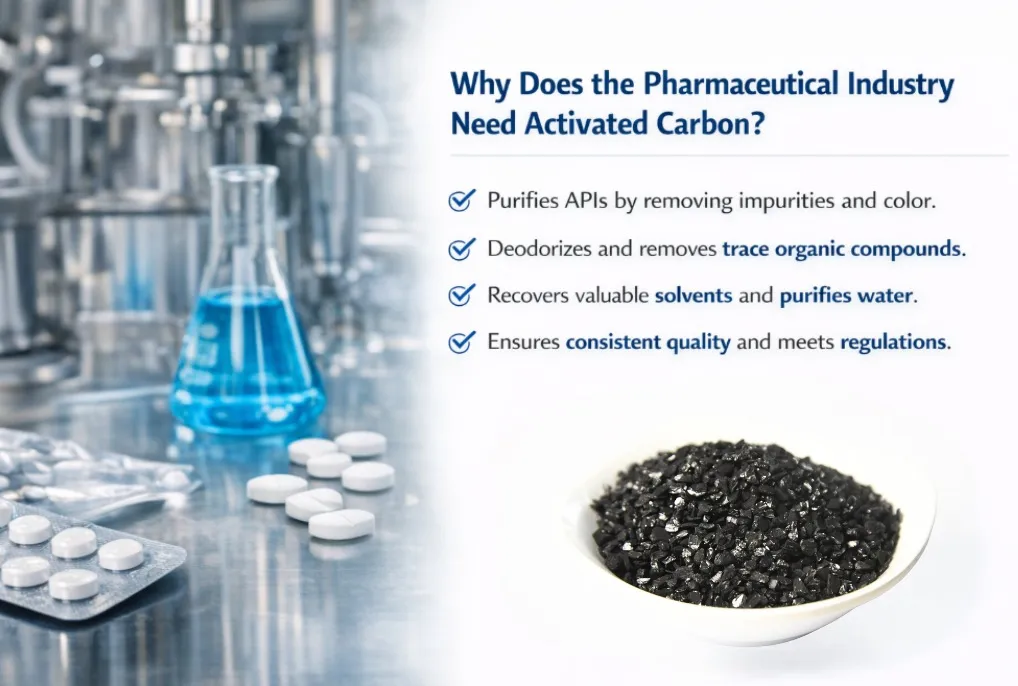

Why Does the Pharmaceutical Industry Need Activated Carbon?

Pharmaceutical raw materials and intermediates are often derived from natural plant extracts, fermentation broths, or complex chemical reaction systems, which typically contain:

- Natural pigments

- Resinous impurities

- High-molecular-weight organic compounds

- Odor-causing substances

- Trace toxic by-products

Even at very low concentrations, these impurities may affect a drug’s appearance, stability, bioavailability, and even safety.

As a highly efficient adsorbent, activated carbon—thanks to its large specific surface area and developed pore structure—can effectively remove impurities and toxic substances, significantly improving pharmaceutical purity and safety.

Main Applications of Activated Carbon in the Pharmaceutical Industry

With its excellent adsorption capacity and advanced pore structure, activated carbon is widely used in key pharmaceutical production stages to remove color bodies, impurities, and odors.

Decolorization of Pharmaceutical Raw Materials and Intermediates

Decolorization is a critical step in the production of antibiotics, vitamins, amino acids, and herbal extracts.

Functions of activated carbon:

- Adsorption of polyphenols, pigments, and colloidal impurities

- Improvement of solution clarity and color

- Enhancement of downstream crystallization and filtration efficiency

Common applications include:

- Vitamin C and B-complex vitamins

- Penicillin and cephalosporin antibiotics

- Herbal extracts and plant-derived active ingredients

Removal of Impurities and Pyrogens

Certain pharmaceutical processes may generate pyrogens (such as endotoxins), which pose serious risks to injectable and sterile preparations.

Activated carbon with appropriate pore size distribution can:

- Adsorb high-molecular-weight organic impurities

- Reduce pyrogen levels

- Improve overall formulation safety

This application is especially common in injectable APIs and bulk drug purification.

Purification of Solvents and Process Water

Large volumes of organic solvents and purified water are used in pharmaceutical manufacturing, and their quality directly affects product performance.

Activated carbon is widely applied for:

- Organic solvent purification and recovery

- Removal of organic contaminants from process and purified water

- Odor removal and trace pollutant control

Within GMP systems, activated carbon is a key adsorption medium in water treatment processes.

Pharmaceutical Wastewater and Exhaust Gas Treatment

Pharmaceutical wastewater typically contains:

- Refractory organic compounds

- Antibiotic residues

- Solvents and reaction intermediates

As a polishing treatment material, activated carbon effectively reduces COD, TOC, and toxic substances, helping manufacturers achieve stable regulatory compliance.

Contact me todayActivated Carbon for Pharmaceutical Applications

Activated carbon used in the pharmaceutical industry must not only offer strong adsorption performance but also meet strict requirements for high purity, low leachable impurities, and process stability. TingyuanCarbon supplies premium wood-based activated carbon and coconut shell activated carbon, specifically designed for pharmaceutical purification applications.

Wood-Based Powdered Activated Carbon

Produced from high-quality wood through high-temperature carbonization and activation, this type of activated carbon features a large surface area, well-developed mesopores and macropores, and fast adsorption kinetics. It ensures rapid contact with pharmaceutical solutions and efficient removal of pigments, colloidal impurities, and certain high-molecular-weight organics.

Key advantages:

- Large surface area and advanced pore structure: High proportion of mesopores and macropores, ideal for adsorbing pigments, colloids, and macromolecular impurities.

- Fast adsorption and high decolorization efficiency: Powdered form allows full contact with liquids, enabling rapid purification—ideal for batch processing.

- Excellent dispersibility: Easily and uniformly mixed into solutions, improving adsorption efficiency and reducing carbon consumption.

- Minimal impact on active ingredients: High selectivity ensures impurity removal while preserving pharmaceutical activity.

- Typical applications: Antibiotics, vitamins, amino acids, herbal extracts, and fermentation broths.

Coconut Shell Granular Activated Carbon

Made from carefully selected natural coconut shells through controlled carbonization and activation processes, this activated carbon offers high mechanical strength, uniform pore structure, well-developed micropores, and extremely low impurity leaching. Its granular form is particularly suitable for continuous operation and fixed-bed systems.

Key advantages:

- High mechanical strength and abrasion resistance: Resists breakage and dust formation, reducing secondary contamination risks in fixed-bed systems.

- Uniform pore size distribution and stable adsorption: Well-developed micropores are ideal for removing trace organic impurities and odors from water and solvents.

- High purity with low leachable impurities: Low ash and soluble impurity content, meeting strict pharmaceutical safety standards.

- Suitable for long-term continuous operation: Long service life and reduced replacement frequency help lower operating and maintenance costs.

- Typical applications: Pharmaceutical water treatment, solvent purification, and fixed-bed adsorption systems.

Conclusion

The widespread use of activated carbon in the pharmaceutical industry clearly demonstrates its vital role in improving drug purity and safety. Whether for impurity removal, decolorization, or enhancing product stability, activated carbon consistently delivers outstanding performance.

We supply premium activated carbon solutions for pharmaceutical purification. Feel free to contact us for professional technical support and customized solutions.