Hydrogen sulfide (H₂S) is one of the most challenging pollutants in industrial gases and air treatment. Its “rotten egg” odor can be detected even at extremely low concentrations, but the real concern lies in its corrosiveness, toxicity, and potential hazards.

Activated carbon, with its excellent adsorption properties, has become one of the most widely used materials for H₂S removal worldwide. In this article, we will provide a detailed introduction to the role of activated carbon in removing hydrogen sulfide, helping you choose the most suitable activated carbon products.

The Necessity of Hydrogen Sulfide Removal

Hydrogen sulfide is not only unpleasant in odor but also poses serious risks to human health, industrial equipment, and regulatory compliance. Therefore, it must be effectively removed in many industries.

- Impact on human health: H₂S is highly toxic. Even low-level exposure can cause headaches, nausea, eye irritation, and other symptoms, while high concentrations can lead to breathing difficulties or even suffocation. Long-term exposure may affect the nervous and respiratory systems.

- Corrosion of industrial equipment: H₂S is highly corrosive to metals, easily damaging pipelines, reactors, and storage tanks, which increases maintenance costs and shortens equipment lifespan.

- Environmental pollution and regulatory pressure: H₂S emissions not only cause air pollution but may also violate environmental regulations. Many countries strictly limit H₂S emissions, making effective control essential for regulatory compliance.

Thus, using activated carbon to remove H₂S is crucial.

The Role of Activated Carbon in H₂S Removal

Activated carbon is widely used for H₂S treatment due to its highly developed pore structure, large specific surface area, and strong adsorption capacity. Its effectiveness in H₂S removal depends on a combination of physical adsorption and chemical reaction:

Physical Adsorption

The rich pore structure of activated carbon allows H₂S molecules to be trapped within its pores. This adsorption process is fast and suitable for treating low-concentration H₂S gas.

Chemical Adsorption

Some activated carbons, such as impregnated activated carbon, can chemically react with H₂S to convert it into harmless substances like sulfates or elemental sulfur, achieving higher sulfur loading and more stable desulfurization performance. This is particularly suitable for high-concentration or continuous desulfurization scenarios.

Activated carbon provides stable and efficient H₂S removal for continuous industrial operations.

Contact me todayApplications of Activated Carbon in H₂S Removal

Thanks to its large surface area and highly developed pore structure, activated carbon is widely used in H₂S control, efficiently adsorbing and removing H₂S from gases. Common applications include:

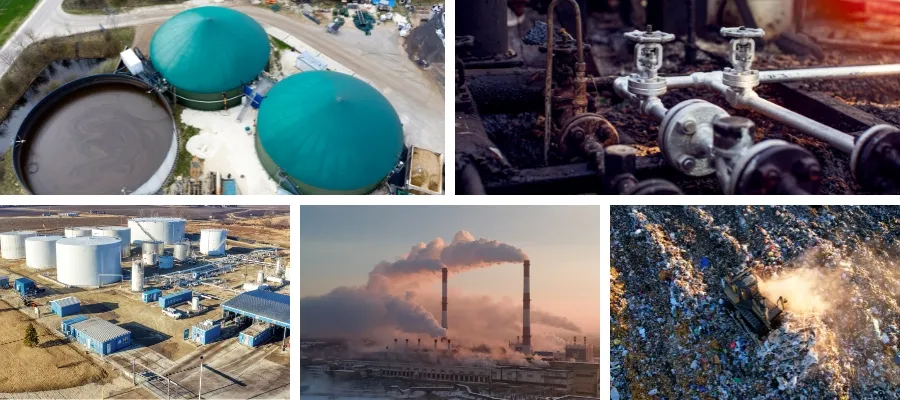

- Wastewater treatment plant exhaust purification: Removes H₂S generated during anaerobic decomposition, improving air quality.

- Biogas and landfill gas purification: Reduces H₂S concentration to protect gas equipment and minimize environmental odor.

- Desulfurization of natural gas and liquefied gas: Ensures fuel quality and prevents pipeline corrosion.

- Petrochemical exhaust treatment: Effectively removes H₂S generated during production, ensuring employee safety.

- Pulp and paper industry exhaust treatment: Reduces sulfide gases, minimizing odor emissions.

- Industrial ventilation and odor control systems: Improves workshop and storage environments while meeting environmental requirements.

With a wide scope of applications, high treatment efficiency, and low operating costs, activated carbon is an ideal choice for large factories and environmental projects.

Activated Carbon for H₂S Removal

Choosing the right activated carbon is key to effective H₂S removal. Tingyuan Carbon, with years of industry experience, has developed and produces activated carbon specifically for hydrogen sulfide removal.

Granular Activated Carbon

Granular activated carbon is one of the most commonly used desulfurization materials, featuring high surface area and uniform pore distribution, suitable for adsorbing H₂S from air or gas.

- Efficient physical adsorption: Micropores capture H₂S molecules from air or gas, removing low to medium concentrations.

- Wide applicability: Can be used in wastewater treatment plant exhaust, chemical waste gas treatment, laboratory ventilation, and other low-concentration H₂S scenarios.

- Flexible operation: Granular activated carbon can be packed in adsorption towers or tanks, allowing easy replacement and maintenance.

Extruded activated carbon

Formed into regular cylindrical shapes through high-temperature extrusion, cylindrical activated carbon offers high mechanical strength, large surface area, and low pressure drop, making it suitable for high-flow and continuous operation, mainly for continuous H₂S treatment.

- Durable and high-strength: Cylindrical form ensures it won’t break under high-speed gas flow, ideal for large desulfurization towers and continuous emission systems.

- Low pressure drop and stable adsorption: Uniform pore structure minimizes gas flow resistance while maintaining stable adsorption capacity.

- Long lifespan and efficient desulfurization: Suitable for continuous removal of medium to high concentrations of H₂S in biogas, landfill gas, and industrial exhaust.

- Wide applications: Widely used in petrochemical plants, biogas power plants, and industrial gas treatment units for long-term stable desulfurization.

Impregnated Activated Carbon

Impregnated activated carbon is treated with chemical agents (e.g., KI, NaOH, KOH) on its surface to enhance H₂S capture through chemical reactions.

- Chemical adsorption and conversion: H₂S is oxidized or converted to stable substances such as sulfates or elemental sulfur for deep desulfurization.

- Suitable for high-concentration and corrosive gases: Ideal for chemical plants, petrochemical facilities, high-sulfur biogas, and landfill gas environments.

- High desulfurization efficiency and long life: Chemical action allows impregnated activated carbon to maintain stable desulfurization performance under high concentrations.

We can recommend the most suitable activated carbon for your specific application and needs.

Contact me todayConclusion

Activated carbon, with its high adsorption capacity, has become the preferred material for hydrogen sulfide control. Tingyuan Carbon, as a professional activated carbon supplier, offers the highest-quality products to efficiently remove H₂S.

- Granular activated carbon

- Pellet activated carbon

- Impregnated activated carbon

- Customized solutions as needed

📞 For bulk purchases or quotation inquiries, feel free to contact us.

We will recommend the most suitable products for your H₂S removal project.