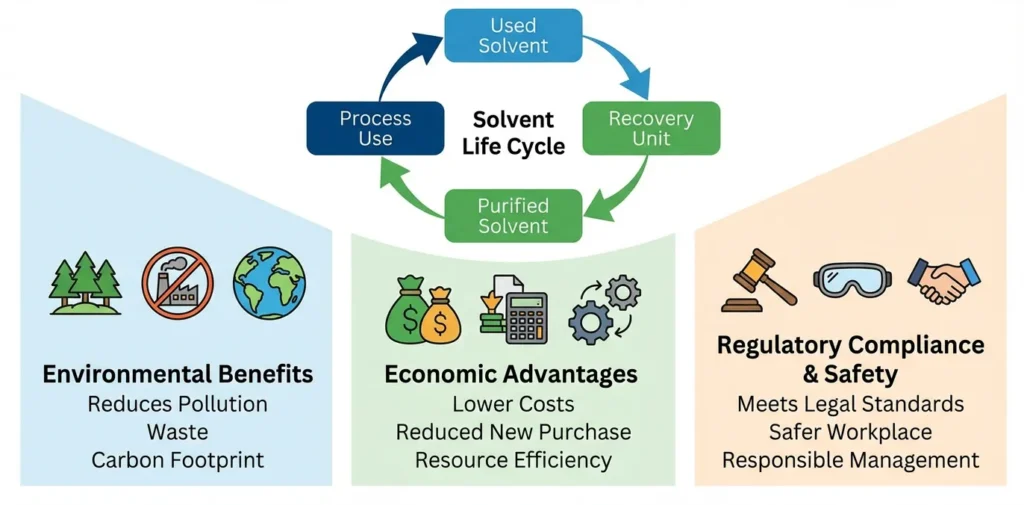

In modern chemical production, organic solvents are widely used due to their excellent dissolution properties. However, these solvents are not only expensive, but their volatile emissions also cause serious environmental pollution. Therefore, solvent recovery is crucial. Traditional condensation methods often struggle to achieve efficient recovery.

Activated carbon, with its excellent adsorption performance, shows outstanding results in solvent recovery. This article will detail the role of activated carbon in solvent recovery and help you choose suitable activated carbon products.

Why is Solvent Recovery Necessary?

Organic solvents are essential raw materials in modern chemical, pharmaceutical, electronics, and other industries. They play core roles in production processes as reaction media, extractants, and cleaning agents. However, solvent losses commonly occur during use:

- Production Process Evaporation: Direct evaporation during coating, printing, and other processes

- Equipment Cleaning Loss: Residue and evaporation of cleaning agents

- Storage and Transportation Losses: Tank breathing and leakage during transfer

Without solvent recovery, this can lead to:

- Economic Losses: Taking toluene as an example, a company using 1000 tons annually with a 15% loss rate could face losses of millions of yuan at market prices.

- Environmental Pressure: Air pollution from VOCs emissions, facing strict environmental supervision and huge fines.

Activated Carbon Solvent Recovery Mechanism

Activated carbon recovers solvents mainly through adsorption, specifically through:

Physical Adsorption Mechanism

- Van der Waals Forces: Attraction between activated carbon surface and solvent molecules through van der Waals forces

- Capillary Condensation: Solvent molecules undergo capillary condensation in micropores and mesopores

- Surface Diffusion: Adsorbed solvent molecules can undergo two-dimensional diffusion on the carbon surface

Pore Structure

Activated carbon has selective adsorption for different-sized solvent molecules based on its pore structure:

- Micropores (<2nm): Mainly adsorb small molecules

- Mesopores (2-50nm): Suitable for medium-sized molecules

- Macropores (>50nm): Act as transport channels promoting molecular diffusion

Adsorption Kinetics Process

The solvent recovery process includes these stages:

- External Mass Transfer: Solvent molecules transfer from gas phase to carbon particle surface

- Internal Diffusion: Molecules migrate through pores into the carbon interior

- Adsorption Equilibrium: Reaching adsorption-desorption equilibrium at specific sites

Specialized Activated Carbon for Solvent Recovery

Choosing suitable activated carbon is crucial for effective solvent recovery. TingyuanCarbon offers high-quality activated carbon products specifically designed for solvent recovery.

Contact me todayCoal-Based Pellet Activated Carbon

Made from high-quality coal through carbonization and activation, this cylindrical product features developed pore structure and high mechanical strength, suitable for large-scale industrial solvent recovery.

Key Features:

- High mechanical strength and wear resistance

- Low pressure drop and air resistance

- Long service life

- Strong acid and alkali resistance

- Relatively low cost

Applications:

- Large coating lines and printing plants

- High airflow treatment systems

- High concentration solvents

- Continuous operation conditions

Coconut Shell Granular Activated Carbon

Made from natural coconut shells through special processing, featuring well-developed micropores, high adsorption capacity, and low impurity content, especially suitable for high-purity solvent recovery.

Key Features:

- Large specific surface area

- Well-developed micropore structure

- High adsorption capacity

- Low impurity content

- Good regeneration performance

Typical Applications:

- Fine chemical solvent recovery

- Small recovery units

- High-purity recovery requirements

- Batch operation conditions

Process Optimization Recommendations

Pretreatment:

- Install dehumidification equipment to reduce moisture interference

- Install pre-filters to remove dust and impurities

Operating Parameters:

- Adsorption Temperature: Below 40℃

- Empty Bed Velocity: Recommended 0.2-0.4m/s

- Relative Humidity: Below 65%

Regeneration Process:

- Steam Temperature: 120-130℃

- Regeneration Time: 2-3h/cycle

- Regular Replacement: Recommended every 2-3 years

Conclusion

Activated carbon adsorption technology provides a perfect solution for industrial solvent recovery. Through selecting high-quality activated carbon products and proper system design, businesses can achieve significant economic and environmental benefits.

TingyuanCarbon has focused on the activated carbon field for nearly 20 years, offering high-quality products and rich application experience. Contact us now for free sample testing and customized solvent recovery solutions.